As the grapes are fed into the Lugana’s feed hopper, a short auger meters them into the rotating destemmer drum. By destemming prior to crushing a superior must is obtained. The sheeting of the destemming drum is with round countersunk holes. This avoids maceration of the fruit and keeps the grape stems intact. The rotary destemming paddles offer the winemaker the possibility of adjusting the destemmer axle for the best operation on specific grape varieties. The speed of the grape infeed auger is adjustable independent of the speed of the destemming paddles.This insures that the flow of grapes through the machine can be optimized for each variety.

The Lugana’s crushing rollers are mounted under the destemming drum so no stems are crushed into the must. The rollers are made of rubber and they are with small teeth in order to have the right crushing action. Two calibrated hand wheels on the outside of the machine allow the operator to set the roller spacing to give the desired amount of crushing.

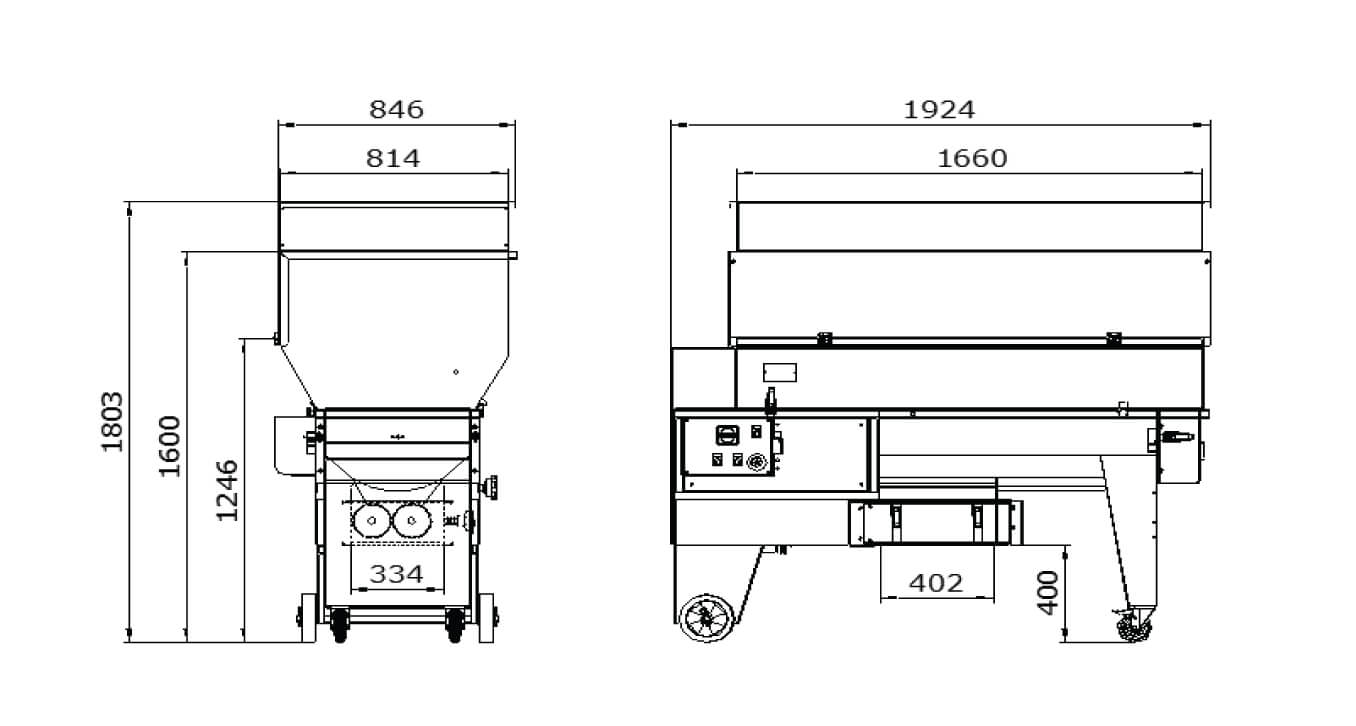

The destemmer-crusher “LUGANA 2 R” in its standard model, is provided with:

Electrical control panel with start/stop buttons, mechanical speed control to adapt the speed to the different worked varieties of grapes, destemming axle with rubber adjustable paddles, drum made of pierced stainless steel sheeting, must gathering tank with in-feed auger that also acts as a must mixer and with fitting for suction pumps.

Whenever you don’t like using suction pumps, you can use many other kinds of pumps equipped with must gathering tank, like pumps with elliptical rotor, mono pumps: you only need to remove the must gathering tank from its slides.

For the most critical winemakers a drum made of plastic material can be supplied (it is an optional). This can be used with manually picked grapes only. For all the wine-industries which need a bigger hopper to unload their grapes, our “LUGANA 2 R” unit can be supplied with a longitudinal hopper on its upper side. This is also an optional (model R-TL).

Sanitation is one of the most critical aspects of winemaking. The “LUGANA 2 R” is designed to be fully disassembled for cleaning in few seconds (fig. 4). So you can easily clean all the parts of the machine that still have pieces of worked grapes.

Its transmission and its motor are completely isolated from the part where the product is worked.

Technical characteristics are not binding. The company reserves the right to make modifications without giving prior notice.